SANRITSU WASHER ASSEMBLY MACHINE

SANRITSU WASHER ASSEMBLY MACHINE |

|||

|

|

||

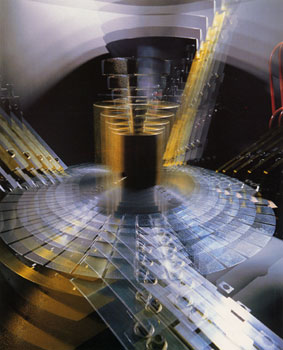

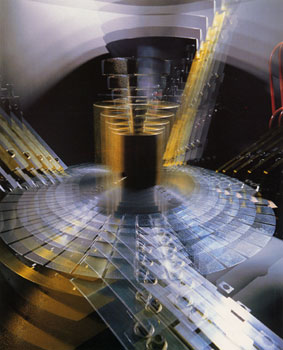

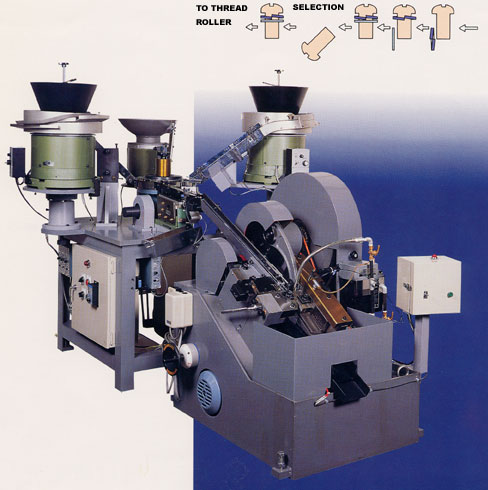

HIGH SPEED WASHER ASSEMBLY MACHINE

|

||||||||

| More than 2,500 units of Sanritsu machines have been supplied and moreover they have been achieving high reputation for newly developed NS-H type machine from a lot of customers. |

||||||||

|

||||||||

|

||||||||

| Specifications | ||||||||

|

||||||||

| * For long shank parts, NS-HL model is also available. * Depending on the type of blanks and washers, output per min. will be changed. |

||||||||

| Features |

||||||||

| *Screw blanks and washers are separately supplied from each vibratory feeder through chutes. Then the blanks are put in an U-notch (divided 360š into 40 sections) of the circular plate and held by the powerful plate spring at the head of screw. As a result, there is no unnecessary vibration of the scrw. *Because of horizontal type blank circular holder, the height of the vibratory feeder can be low and that makes it easy for the operator to see if enough blanks and washers are left or not. *When the size of the washers are changed, only the chute must be changed. (When the size of the screws are changed, some more parts (such as bowl of vibratory feeder etc.) have to be changed.) *Abnormally assembled products are completely separated on the chute. (PAT.) *Very much suitable machine for short shank length parts. *By turning the up-down adjusting wheel, machine is easily adjusted to the different shank length parts. |

||||||||

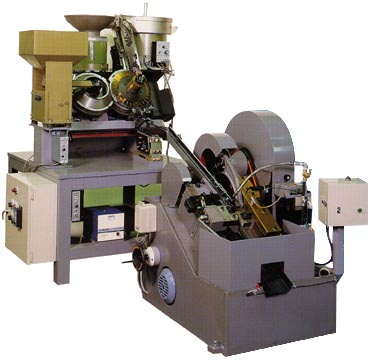

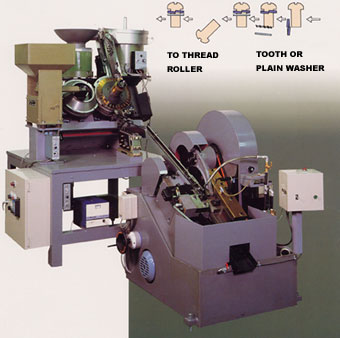

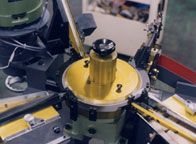

HIGH SPEED WASHER ASSEMBLY MACHINE

|

||||||

| Tooth washers are usually the cause of trouble on the feeding chute. But this machine adopted non-chute feeding mechanism and eliminate the reason of trouble. |

||||||

|

||||||

| Specifications |

||||||

|

||||||

| * Depending on the type of blanks and washers, output per min. will be changed. |

||||||

| Features |

||||||

| *Tooth or plain washers are fed from the hopper without chute to the rotary washer feeder. Rotary washer feeder are inclined 5° to screw feeder. Washers are picked up by screw blank and assembled. |

||||||

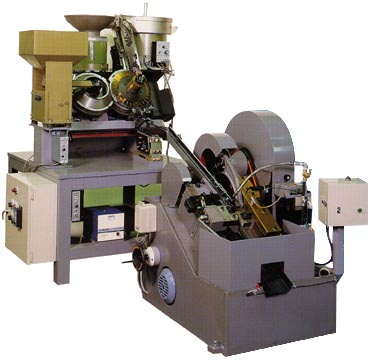

HIGH SPEED WASHER ASSEMBLY MACHINE

|

|||||

| Specifications Screw Dia. : M1.0~M2.0 Shank Length : 4mm~10mm |

|||||

|

|||||

|

|

||||

| Features | |||||

| What makes NS-S type machine different from conventional (NS-H type) assembly machines is its unique chute. Conventional machines use the weight of washers to feed them, however it is hard to feed micro size washers by using their own weight. The chute of NS-S type is inclined 15° to left side and inclined 10° to forward to eliminate this trouble. Moreover the machine is equipped with vibrator right under the chute. NS-S adopts the circulation type vibratory hopper. The washers fed by vibratory hopper are oriented into the groove of the chute and extra washers come back to the bowl of vibratory hopper. Thus, the washers are fed smoothly and accurately. And regardless of the screw dia, special washers which are difficult to feed can be fed smoothly by changing the chute. SPECIFICATIONS: M1.0 ~ M2.0 SHANK LENGTH 4mm ~ 10 mm |

|||||