Ordinary Appearance.

Striking Technology.

| NISSHIN alpha DIES | |||||||

|

Ultra Long Life. Ordinary Appearance. Striking Technology. |

||||||

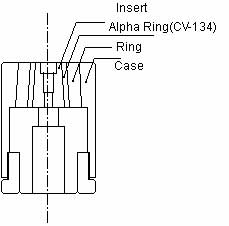

| Alpha die is composed of multi-rings of different materials and is designed to absorb strength and toughness in good balance. Namely, a ring which is strong radially and another ring which is strong circumferentially are assembled keeping good balance. Moreover, internal distortion is eliminated by unique manufacturing method to keep high accuracy of dies. This has greatly improved die life. | |||||||

| What is the alpha Die? | ||||||||||

|

||||||||||

| Alpha Dies is an unique cold forming die, which is composed of a combination of carbide insert, multiple rings and die case. Because of its special ring material and manufacturing method, you can expect 3 -10 times longer tool life than conventional dies. | ||||||||||

| Why is the life of alpha Dies so long? | ||||||||||

| One reason is that they adopt most suitably selected material for reinforcing rings called CV-134. Another reason is that distortion, which is always caused by internal stress in an assembled condition, is completely eliminated in advance by machining outside of the dia. in a condition that a dummy insert is put in. Therefore, alpha Dies can keep their outside dia. in accurate round shape even in a finally assembled condition and that leads to longer life. |

||||||||||

|

||||||||||

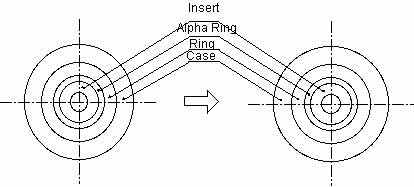

| How to replace the insert? | ||||||||||

| After insert is wore or broken, please push out only insert and just press fit new one. Normal, alpha case (alpha Ring + Ring + Case) can repeatedly be used more than 10 - 15 times. That is very much cost effective. | ||||||||||

| Sample Products Manufactured Using Alpha Dies | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 1 |  |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 6 |  |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 7 |  |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 2 |  |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 8 |  |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 3 |  |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 4 |  |

No. 9 |  |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 10 |  |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 5 |  |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 11 |  |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Stainless Steel Screws Manufactured using alpha Dies |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| In cold forming industry, products of intricated shape and high precision have been increasingly requested. At the same time, cost reduction by increasing productivity has been also demanded. Such being the case, longer life and break-free tooling at high speed operation has been vitally important and awaited. We are pleased to advise you that our tool manufacturer NISSHIN has developed alpha Dies in order to meet this demand. alpha Die is composed of an insert and alpha Case (Insert Nib Holding Ring + Ordinary Reinforcing Ring + Case). alpha Dies have been successfully used by about 45 leading fastener and parts manufacturers in Japan for the last 7-8 years and the life has been proved by them to be extremely long. The reports from these manufacturers say that life of such dies (insert nibs) has been normally 3-10 times longer than conventional ones and that the same alpha Case (Insert Nib Holding Ring + Ordinary Reinforcing Ring + Case) can be reused 10-15 times by replacing only insert nib. The prices for completed a Dies are about 3 times higher than conventional dies, but the above mentioned advantageous features can largely reduce total tooling cost in the long run. Life of insert nibs is about 3-10 times longer. (#3 die on FORMAX 200pcs/minute more than 30 times.) Moreover, a Case which shares large portion of total die price can be reused 10-15 times repeatedly. NISSHIN explains about the history and features of alpha Dies as below: Conventionally, tool manufacturers have been using Tool Steel, Nickel Chrome Molybdenum Steel, Nickel Chrome Steel or Chrome Molybdenum Steel for the conventional die case so as to obtain high tensile strength. NISSHIN thought, however, that more suitable material must be selected, because high stress is repeatedly caused from inside of a die. In a die, when internal pressure is given, not only radial stress is caused toward outside but also circumferential stress is caused. Namely, for a die case, high strength is required against radial stress and high toughness is required against circumferential stress. The conventional die case was not strong enough (particularly in case of thinner die case) for such high stress. NISSHIN alpha Dies have been developed to eliminate such defect. Each of them is installed with insert nib holding ring and ordinary reinforcing ring of different materials. It must be noted that a ring which is strong against radial stress and a ring which is strong against circumferential stress are assembled into one alpha Die keeping a good balance. (They chose the most suitable material for each ring from their various experiences.) Moreover, those rings are assembled eliminating internal distortion by NISSHINŐs unique manufacturing method. These are the main reasons why life of a Dies has been drastically improved. In comparison with conventional die (single reinforcement), life of NISSHIN alpha Dies (inserts nibs) is normally 3-10 times longer than conventional ones and when the insert nib is worn out, only the insert can be replaced and the alpha Case can be used repeatedly . This means that you can reduce the cost and stock space for dies dramatically. (You would easily be able to imagine how big merit is brought by alpha Dies if you need 80 different dies.) In addition, if designing of the alpha Case is discussed with you at the beginning, we can so arrange that insert nibs for different products can be commonly used with the same alpha Case (Insert Nib Holding Ring + Ordinary Ring + Case). *Important features are (1) NISSHIN alpha Case (Insert Nib Holding Ring + Ordinary Reinforcing Ring + Case) is manufactured in a special way (giving internal stress) that does not cause distortion of insert nib when the insert is assembled into alpha Case and (2) NISSHIN uses special material for insert nib holding ring in order to increase the life of alpha Die. |

|