|

||

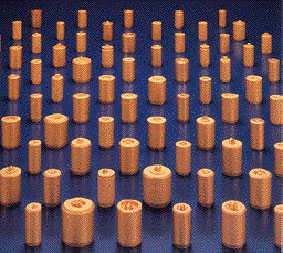

| “NHK” Header Punches | ||

|

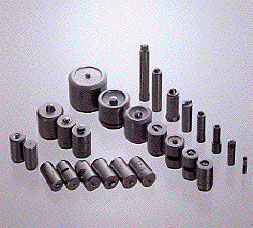

1. NHK is one of the biggest manufacturers of header punches in the world both in supply volume and in variety of punches. 2. NHK is one of the group companies of NHK Spring Co., Ltd. who includes also Topura - leading Japanese screw manufacturer for automobile industry and various kinds of other screws and parts. 3. NHK punches are produced in specialized plants where the most modern equipments are used and computer control system performs perfect quality, production and inventory control. This high quality and extensive product lines have earned the trust and admiration of the world. 4. Another big advantage is that NHK provides prompt and reliable delivery at any time. 5. In addition to the world’s representative screw standards - ANSI, DIN, BS, JIS, NHK can supply special punches in accordance with customers specifications such as combination punches, plug gauges, Q-check gauges, etc. 6. It is convenient to know that NHK can supply punches in metric and inch size body dimensions and with and without clamping groove. 7. In order to be competitive, prices of standard punches have been reduced and maintained to the minimum level while prices for special punches are quoted as special ones. 8. One remarkable development NHK has achieved and would like to recommend is Punches with surface treatment “PICA-ICHI”. |

|||

|

||||

|

|

|||

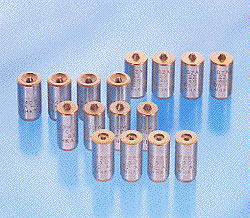

| Features of NHK Coated Punches “PICA-ICHI” | ||

| • Type of coating is CVD (Chemical Vapor Deposit) and it is hard and ideal hard anodic oxide multi layer coating. • The hard anodic oxide coating is thoroughly studied from soft-ware side and hard-ware side and consistent. • The dimensions and designation of the punches are ideal that can be achieved only be well and long established manufacturer of punches. • Features of high speed steel for basis have been well enough utilized. • Precision outer diameter of punch body and concentricity have been excellently maintained. • The quality is consistent because of continuous production. |

||

| NHK’S PICA-ICHI COATING |

|||||||

| CLOSER TO DIAMOND AND YET CLOSER TO STEEL! |

|||||||

| IS PICA-ICHI DOUBLE LAYER COATED? IT IS ACTUALLY TRIPLE! LAYER COATINGS. | |||||||

| Hardness Comparison | |||||||

| The hardest material on the earth is diamond. It is well and widely known that diamond is superior in weariness and is industrially indispensable. On the other hand it is very expensive, hard for processing, and weak against impact and heat, etc. | |||||||

| Hardness is not a single factor to be ideal for making punches | |||||||

| It is without saying that the first purpose to apply coating to tooling such as punches and other wear resisting tools is to improve weariness. Diamond is No.1 in hardness and weariness, but because of other features of diamond it can not be suitable for making punches. So, the practical best coating must be the one that is hard, strong against impact, good contact to base material, suitable to work piece material, etc. | |||||||

| CVD or PVD | |||||||

| In thin vapor depositing coating systems, there are briefly 2 ways well known. One is CVD (Chemical Vapor Deposition) and the other is PVD (Physical Vapor Deposition). Both ways have merits and demerits respectively, but punches are supposed to be used under one of the severest conditions and Pica-Ichi is treated by CVD as it gives the strongest coating film. | |||||||

| Basic Concept of Pica-Ichi | |||||||

| NHK believes that quality of coated punches depends on the following 3 main factors. | |||||||

|

|||||||

| Base Material of Punches | |||||||

| Strength of base material is the real basic factor for shapes, dimensions and life of punches. Suitable selection of material and well considered heat treatment (particularly heat treatment after coating) determine the strength of base material. | |||||||

| Coating Film | |||||||

| Punches are used under one of the severest conditions. They are, therefore, requested to be hard and wearable enough. In addition, good contact to base material, suitability to screw material, seizure resistance are required. So, the coating film and the thickness are vitally important. | |||||||

| Surface Finish | |||||||

| On one side coating film is hard and wear resistant, but on the other side it is brittle. It is, therefore, important to eliminate sharp edges and improve surface roughness so that cracks and chipping of coating will be less and suitability of coating to base material will be better. | |||||||

| Types of Coating Films and Physical Properties of Pica-Ichi |

|||||||

|

|||||||

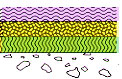

| Sectional Condition of Pica-Ichi Coating Films and the Features | ||||

|

||||

| TiN: In comparison with TiC, hardness is low and friction coefficient is larger, but contact to steel is lower and this prevents galling or seizure and works as lubrication effect. | ||||

|

||||

|

||||

| TiCN: This is combined coating film of TiC and TiN and has features of medium of both. This works as absorbing different coating films in thermal expansion coefficient. | ||||

| TiC: This has good contact to base material. This is also hard and wear-resistant. | ||||