on technology's cutting edge.

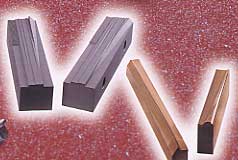

Since our organization took its first steps in the automotive manufacturer related field, we have been crafting die-plate for the form-rolling processing of specialty screw forming-parts and responding to the high standards of our customers' demands with advanced technical prowess and novel ideas.

Along with the shift toward higher performance and efficiency in industrial products has come the necessity for specialized and precision technologies in the design and production of die-plate. Applying the highest in technological standards and know-how, we are supporting the development of Japan's key industries with precision forming parts manufacture as our mainstay, providing rolling-form die-plate for parts that previously relied on cutting by machine tools for their production.

With development of international patents for die-plate and other activities, we've got our sights firmly trained on the industry's cutting edge.