|

|

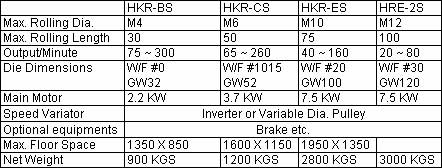

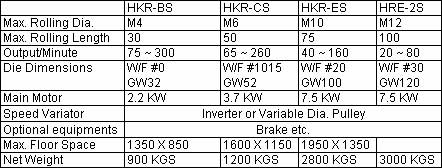

(M2 - M4) High Speed Rolling Machine |

|

|

|

Features

As the results of the most up-to-date improvements in dynamic balance, decreasing weight of moving area and parts, etc., stable and super speed operation has been realized.

Stable start even at high speed has been achieved because of 20 degree wedge type starter (die steel) mechanism.

Tool steel and special bronze materials are used for sliding section. As the results of severe accuracy control of the section, high precision thread and form rolling is practical and reliable.

Chute rail is treated with induction hardening, moreover hardened chip installed at the lower edge of the rail is replaceable.

The most suitable speed for each blank can be selected freely and easily by turning the volume of inverter. Output per minute can be read directly in a digital indicator.

Working height is designed to be comfortable and healthy for operator.

|

|

|

MODEL HKR-B3 (M4) |

|

|

|

Specifications

Machine Type: HKR-B3

Max. Thread Diameter: M4

Max. Thread Length: 30 mm

Output/minute: 100 - 400 pcs.

Die Dimensions: W/F #0, GW32

Main Motor: 3.7 kw

Speed Variator: Inverter*

Blank Feeder: Vibratory Feeder*

Optional Equipments: Various Checkers and Vibratory for chute etc.

Measurement: 1,350 x 950 x 1,600 mm

Weight: 900 kg

*Other types of speed variators or blank feeders are also available on request. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(M4 - M6) High Speed Rolling Machine |

|

|

|

Features

As the results of the most up-to-date improvements in dynamic balance, decreasing weight of moving area and parts, etc., stable and super speed operation has been realized.

Stable start even at high speed has been achieved because of 20 degree wedge type starter (die steel) mechanism.

Tool steel and special bronze materials are used for sliding section. As the results of severe accuracy control of the section, high precision thread and form rolling is practical and reliable.

Chute rail is treated with induction hardening, moreover hardened chip installed at the lower edge of the rail is replaceable.

Recognized rigidity has been further increased. More powerful motor (5.5 kw) has been employed. These improvements meet wider range of harder applications.

The most suitable speed for each blank can be selected freely and easily by turning the volume of inverter. Output per minute can be read directly in a digital indicator. |

|

|

|

MODEL HKR-C3 (M6) |

|

|

|

|

Specifications

Machine Type: HKR-C3

Max. Thread Diameter: M6

Max. Thread Length: 50 mm

Output/minute: 80 - 330 pcs.

Die Dimensions: W/F #1015, GW52

Main Motor: 5.5 kw

Speed Variator: Inverter*

Blank Feeder: Vibratory Feeder*

Optional Equipments: Various Checkers and Vibratory for chute etc.

Measurement: 1,600 x 1,150 x 1,700 mm

Weight: 1,300 kg

*Other types of speed variators or blank feeders are also available on request. |

|

|

|

|

|

|

|

|

|

|

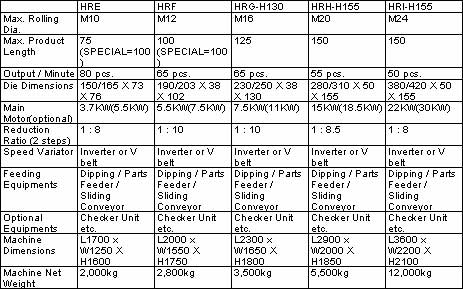

M8 Middle Speed Rolling Machine

High speed and efficiency for M6 - M8 class thread rolling.

High accuracy for ø5 class groove making and form rolling operation.

Excellent in every point, such as accuracy, power,functions, easy operation, etc. |

|

M8 Middle Speed Rolling Machine

High speed and efficiency for M6 - M8 class thread rolling.

High accuracy for ø5 class groove making and form rolling operation.

Excellent in every point, such as accuracy, power,functions, easy operation, etc. |

|

|

|

Features

Strict accuracy control of sliding area, which is made of die steel and special bronze materials, allow high precision thread and form rolling operation.

Chute rail is treated with induction hardening, moreover hardened chip installed at the lower edge of the rail is replaceable.

It equipped with hanging device (40 mm) which is convenient for rolling long shank parts, large dia. parts, etc. Rolling above flange is also possible by lowering chute rail. (option)

Stable start has been achieved for various shapes of blanks, because of 20 degree wedge (die steel) type starter mechanism.

Rigidity are strengthened and 5.5 kw motor type is optionally available. The machine can cope widely with more difficult parts.

The machine is equipped with non-step variable speed controller so that the most suitable speed can be freely selected for each product. On inverter type, output/min. can be found in digital panel. |

|

|

|

MODEL HR-DM (M8) |

|

|

Specifications

Machine Type: HKR-E

Max. Thread Diameter: M10

Max. Thread Length: 75 mm

Output/minute: 55 - 200 pcs.

Die Dimensions: W/F #20, GW100

Main Motor: 7.5 kw

Speed Variator: Belt Drive Nonstep Speed Variator*

Blank Feeder: Vibratory Feeder*

Optional Equipments: Various Checkers and Brake Motor etc.

Measurement: 2,200 x 1,350 x 1,800 mm

Weight: 3,000 kg

*Other types of speed variators or blank feeders are also available on request. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

M10 High Speed Multi Function Rolling Machine |

|

|

|

Features

As the results of the most up-to-date improvements in dynamic balance, decreasing weight of moving area and parts, etc., stable and super speed operation has been realized.

Stable start even at high speed has been achieved because of 20 degree wedge (die steel) type starter mechanism.

Tool steel and special bronze materials are used for sliding section. As the results of severe accuracy control of the section, high precision thread and form rolling is practical and reliable.

Chute rail is treated with induction hardening, moreover hardened chip installed at the lower edge of the rail is replaceable.

Convenient up and down adjusting system is adopted for chute rail. This enables rolling under blank hanging condition in case of long shank length, half thread screws, square neck screws and screws with large flange at middle part of shank. By lowering chute rail, portion above flange can be also rolled.

Non-step variable speed changer is mounted as a standard design. Brake motor is available as optional equipment. The convenience will be surprising. |

|

|

MODEL HKR-E (M10) |

|

Specifications

Machine Type: HKR-E

Max. Thread Diameter: M10

Max. Thread Length: 75 mm

Output/minute: 55 - 200 pcs.

Die Dimensions: W/F #20, GW100

Main Motor: 7.5 kw

Speed Variator: Belt Drive Nonstep Speed Variator*

Blank Feeder: Vibratory Feeder*

Optional Equipments: Various Checkers and Brake Motor etc.

Measurement: 2,200 x 1,350 x 1,800 mm

Weight: 3,000 kg

*Other types of speed variators or blank feeders are also available on request. |

|

|

|

|

|

|

|

|

|

|

|

|

|

Features

Stable start has been achieved for various shapes of blanks, because of 20 degree wedge (die steel) type starter mechanism.

Strict accuracy control of sliding area, which is made of die steel and special bronze materials, allow high precision thread and form rolling operation.

Chute rail is treated with induction hardening, moreover hardened chip installed at the lower edge of the rail is replaceable.

Convenient up and down adjusting system is adopted for chute rail. This enables rolling parts with long shank length, half thread, square neck and large diameter possible. Also by lowering chute rail, rolling above flange is possible.

Non-step variable speed changer is mounted as a standard design. Brake motor is available as optional equipment. The convenience will be surprising. |

|

|

|

MODEL HR-FM (M12) |

|

|

Specifications

Machine Type: HR-FM

Max. Thread Diameter: M12

Max. Thread Length: 100 mm

Output/minute: 120 pcs.

Standard Dies: 190/203 x 38 x 102H (W/F #30)

Main Motor: 11 kw

Speed Variator: Belt Drive Nonstep, Variable Speed Motor

Blank Feeder: Vibratory Feeder, etc.

Optional Equipments: Various Checkers and Brake Motor

Measurement: 2,200 x 1,400 x 1,800 mm

Weight: 3,800 kg |

|

|

|

|

|

|

|

|

|

|

|

|

|

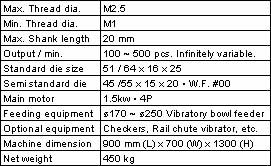

In addition to thread rolling, the machines realize various jobs such as roll forming of V grooves, R grooves, knurls and groove knurl combined, radius point, cone point w/radius tip, chamfer point and even burnishing of shaft and spherical part at low tool cost of flat dies at higher speed and more reliable and consistent accuracy than cutting operation.

Roll forming is the lowest cost operation and horizontal type machine is the best basic machine. |

|

|

|

Features

Severer controlled accuracy of recognized slide mechanism enabled high precision thread and form rolling.

Because of level design of slide, unbalanced design blanks (top heavy, barrel type shank, extremely small head dia.) or headless design blanks can be rolled excellently.

2 types of feeders, Pipe Type and Special Chute Rail Type are available.

Low feeding position and high discharging position assure higher workability.

In Pipe Type feeder, 1 Piece Feed Device and Blank Bottom Support Positioning Device with scale is employed.

In Chute Rail Type feeder, 2 pcs. vibrators or straight feeder is employed to help smooth flow of blanks. |

|

|

|

MODEL HRE-2S (HORIZONTAL) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|