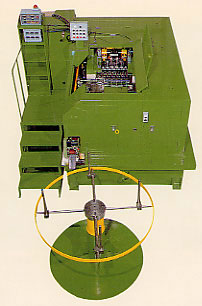

| FUJISAWA FORMER | |

|

|

|

|

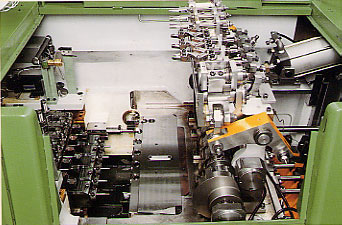

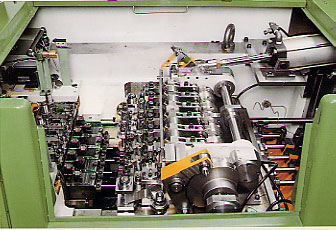

| DOUBLE CAM FORMER | |

|

|

| MODELS (Figures after - is the number of stations.) | ||||

| SIZES FROM ø11 ~ ø32 ( NUT FORMER AND PART FORMER ) FROM ø6 ~ ø22 ( BOLT FORMER ) NUT FORMER WITHOUT PKO WITH PKO PART FORMER • FN-3 • FN-4 • FNP-4 • FP-4 • FN-5 • FNP-5 • FP-5 • FP-6 BOLT FORMER • FPB-3 • FPB-4 • FPB-5 • FBT-5 • FPB-6 • FBT-6 |

||||

| FEATURES | ||||

| • High Accuracy Abnormal Detector Checker Easy to use. Detect Abnormality in wide range adopting double sensor. Near operator free operation can be achieved. • Aluminum Clutch & Brake made in Germany Stops instantly and overload to motor is low. It helps to minimize the required time for set change and trial run. • Aluminum Transfer Mechanism Simple Mechanism. Special aluminum alloy is used for chuck. • Product Eject Conveyor Height of product discharge point becomes low and low recently. But we keep the height 900 mm from the floor, which we believe the best by ergonomics. • Up and Down type wire stand Prevent the unevenness of the material feed. Regardless of the quantity, even supply can be achieved. |

||||

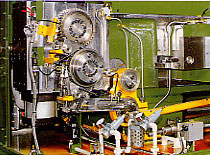

| AT SETTING CHANGE | |||

|

|||

| IN OPERATION | |||

|

|||

| ROTATE DOUBLE CAM MECHANISM NUT FORMER | |

| In addition to our excellent technical design, the drive system of our machine has changed from conventional turn buckle to DOUBLE CAM TRANSFER MECHANISM (PATENT PENDING). 20% more productivity can be expected. • 150 pcs. output per minute in case of 16 mm dia. • As the drive part becomes compact, the width of the machine is reduced 250 mm compared to the conventional model. Space of the operator side becomes bigger, so the maintenance such as tooling change and adjustment is easy. • Further to Double Cam Transfer Mechanism, many special mechanism ( Patent Pending ) are adopted. In addition to high speed and stability, easiness of use is pursued. • Equipped also for 5 station type machine, it performs well for special parts. |

|

|

|

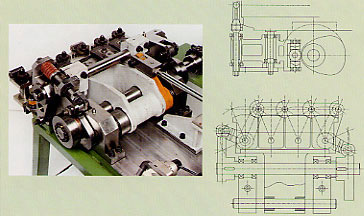

| DOUBLE CAM CUT OFF MECHANISM ( PATENT PENDING ) |

||||

|

When double cam mechanism is mounted on cut off, the spring is compressed at the time the material is fed, so that high speed operation is achieved because the vibration at operation becomes very low. It eliminates the meaningless movement and efficiency and safety are increased. • As the overarm ram is hollow type, the impact to the punch part is absorbed. • As the PKO is located upper part of the ram, timing can be adjusted smoothly. • Simple design and easy to use. Cutter knife can be reached from operation side. ( In case of 17 mm dia. former ) • Conveyor for product discharge is inside the machine. • Safety sound absorbing cover is equipped and noise at operation is prevented. • Non step speed change can be done by inverter. |

|||

|

||||

| Abnormal Detect can not be ignored for quality control. No matter how hard you check you can not have absolute confidence to the product if there is a possibility to overlook the abnormality. This checker brings out the strength when carefulness is required. | |||||||

| High accuracy abnormal detect checker. | |||||||

| Anyone can operate by one touch and abnormality can be checked by double sensor. | |||||||

• Just switch on the electric power, then micro computer follows the fluctuation of the machine automatically and detect without fault. After detecting the abnormality, only you have to do is push the limit switch. • Just switch on the electric power, then micro computer follows the fluctuation of the machine automatically and detect without fault. After detecting the abnormality, only you have to do is push the limit switch.• Double sensors check the two points. Eccentric weighting due to bottom dead center fluctuation can be detected. In addition to overload, empty heading, and double heading, cracks and chips of the punches and dies can be detected. • Non contacting linear sensor is adopted. No trouble and long life. • Absolute value, average value and deviation can be measured by the micron. Appropriate abnormal measurement for each machine is judged. History of tool weariness can be recognized. • The way and the condition of measurement can be changed during operation. As the figures are displayed digitally, reading is easy and abnormal status can be recognized smoothly. • Alarm lamp which can be seen from the distance is equipped. • Timer value (unit/minute) and counter value (unit/100) can be set to control the production. |

|||||||

| Aluminum Clutch & Brake made in Germany | |||||||

|

|||||||

| We have modified Aluminum Clutch & Brake made in Germany to be more robust and hard to be broken. This is used for brake part. Instant stop can be possible and overload to the motor is the lowest comparing with other clutches. This improves the parts life tremendously. | |||||||