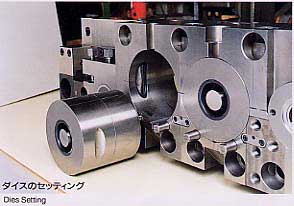

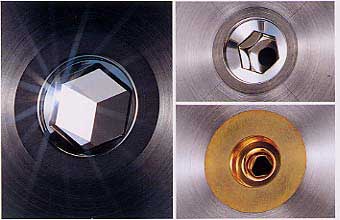

Using the forging process, ATAISU dies contribute a vital part improving quality, increasing productivity and achieving goal of reaching lower product cost.

We ATAISU are totally dedicated and committed in producing the most precise die, using our many years of expertise in production and forging technology field.

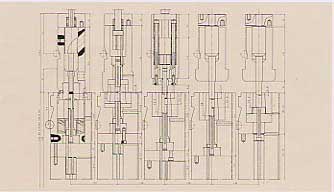

We ATAISU work not only as the forging die maker but also concentrate our efforts in the study and development field positively challenging the limitless possibilities of a unique perfect forging die. We establish rational systems corresponding to our customer expectations and needs. ATAISU contribution to industry and technology our leadership in continuous improvement and new technology build pride and passion in our die production and study in response to the ever changing variety of production kinds that are part of our current age.