One Touch Tap Replacement, Preset of Ration of Rotation, Double Cover for Tapping Oil, etc.

|

|||||||||||||||

| SUPER-2NRSA | M2.6 ~ M5 | ||||||||||||||

| The machine is versatile and corresponds both to the production of small lot of different products and to the production of high volume products of round, flange, hexagonal and square nuts of small dial. | |||||||||||||||

|

Features | ||||||||||||||

| Every size parts for round, flange, hexagonal and square nuts can be set by replacing change parts of main body to suit for each shape. | |||||||||||||||

| The main spindles of left and right side are operated independently by 2 motors. In case that one spindle stops, another spindle keeps operating. |

|||||||||||||||

| If feeding devices (hoppers) are mounted independently for each spindle (optional), nuts of different sizes and shapes can be tapped simultaneously on one machine. | |||||||||||||||

| Highly efficient Abnormal Operation Detector (optional) detects all the estimated abnormal operations by Torque Curve Control such as Empty Tapping, Nut Stuck, Abnormal Biting, etc. and prevents defect nuts from being tapped and mixed. |

|||||||||||||||

| SUPER-2NRSA with Optional Equipments | |||||||||||||||

| The machine is equipped with well reputed equipments of the series (SUPER-NA/NFA/NRA) for easy operation. One Touch Tap Replacement, Preset of Ration of Rotation, Double Cover for Tapping Oil, etc. |

|||||||||||||||

|

|||||||||||||||

| Independent 2 motors allow each spindle to be operated separately. |

|||||||||||||||

|

|||||||||||||||

|

|

|||||

| SUPER-2NRS Guide | Pusher Force can be changed easily by replacing spring. | |||||

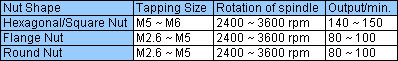

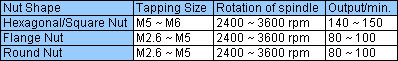

| SPECIFICATIONS | ||||||

|

||||||