|

||||||

|

||||||

|

||||||

NOT THE REVERSE TYPE MACHINE, YET CONTINUOUSOPERATION BY USING STRAIGHT TAP.HOW IS IT POSSIBLE? BECAUSE IT IS SHIMAZU! |

||||||

|

|||

|

|||

CONCEPTS OF DEVELOPMENT |

||||

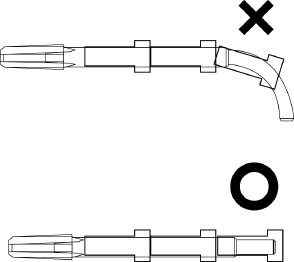

| Long nuts could not be tapped by conventional tapping machine using bent shank taps because the nuts can not go through the bent part of the taps. This is a special tapping machine developed for long nuts using straight taps. Continuous tapping by straight tap is realized just like using bent taps. Because of non-reversing operation, high quality threads are ensured.

Tap is attached to the main spindle when the tapping operation is actually done. When discharging the tapped nuts, the tap is separated from the main spindle automatically. This enables continuous tapping Further more newly developed hydraulic chucking mechanism is equipped which is capable of tapping any nuts such as hex, square, flange and round nuts. The change parts for round nuts is dramatically simplified compared to the conventional machine and the cost and speed for changing the parts is reduced. Also, taking workability and environment into consideration, the operation area is designed to be around 1000 mm from the floor, so the maintenance is easily done. Covers for prevent the cutting oil splash is improved and less splash oil eject nozzle is adapted. |

|

|||

|

||||

BASIC SPECIFICATIONS |

||||||||||||||

|

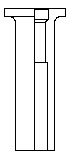

Figure of the products to be tapped Max. outside diameter ø50 mm |

||||||||||||||

| Length of the tap 450 mm |

||||||||||||||

|

Chucking mechanism (change parts for the guide part) |

||||||||||||||

| The nuts can be chucked very strongly by hydraulic and lever.

Fixed side chuck (Lower passive side): R shaped ... 2 pcs. |

||||||||||||||

|

||||||||||||||

|

Main Motor Max rotation of the main spindle 1500 rpm by 2.2 kw induction motor (inverter control) |

||||||||||||||

REMARKS |

||||||||||||||

|

Tap change Oil shortage detect function |

||||||||||||||

EXAMPLE OF CURRENT APPLICATION |

||||||||||||||

| Nut: Round flange nut (flange dia. ø36, Body ø22, length 88 mm) Tap: M14 X 1.5 pitch (6 flutes) Thread length: About 24 mm (thread size M14 X 1.5) Rotation: 840 rpm (thread setting 43) Output: 18 pcs. /minute (total of two spindle) |

||||||||||||||